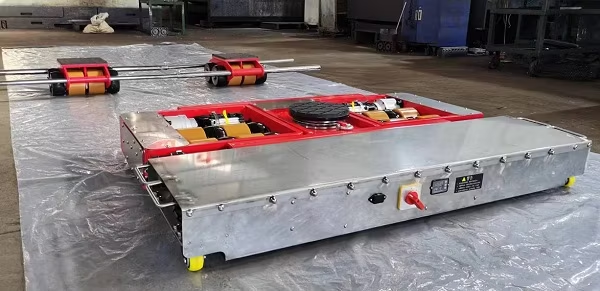

When it comes to moving heavy equipment or machinery, safety is a top priority. Battery-powered machine skates can transport loads. They are a solution that does not rely on cranes or forklifts. Yet, like any technology, these devices must have safety features. They must ensure the safety of both the operators and the load. This article will explore a safety system for battery-powered load-moving skates. It will address key safety concerns and how to reduce risks.

What Are Battery-Powered Machine Skates?

Advanced transport systems are battery-powered machine skates. They move heavy loads with minimal effort. These skates usually have rollers or wheels. They help to slide heavy equipment across smooth surfaces. Unlike manual skates, battery-powered ones use electric motors to move. They require much less effort. They are more efficient and less tiring.

Importance of Safety in Battery-Powered Skates:

Safety is a top concern with heavy-duty transport equipment. This is true in environments where loads are sensitive or hazardous. They may damage infrastructure or harm people. Battery powered machine skates, despite their high efficiency, present certain risks.

Load Instability:

Without proper safety measures, the load can shift. It may become unstable, causing accidents.

Electrical Hazards:

These skates run on electricity. So, there is a risk of short circuits, malfunctions, or battery accidents.

Operator Protection:

Operators must protect themselves from risks. They could catch themselves between the skates and other objects. Malfunctioning parts could also injure them.

Given these concerns, designing an effective safety protection system is essential.

Key Components of a Safety Protection System:

Load Stabilization Mechanisms:

A key concern when moving heavy loads is their stability during transit. You should equip battery-powered skates with systems like:

Load-securing straps:

These can prevent the load from shifting or falling off the skates during movement.

Anti-slip mats:

Anti-slip materials on the skate surfaces reduce load movement and improve stability.

Gyroscopic sensors:

These sensors can detect tilting or instability and activate corrective measures.

Overload Protection:

Battery-powered skates often have weight limits. Exceeding them can cause failure or overload. To prevent such incidents, an overload protection system is crucial. Features could include:

Automatic load monitoring:

Using sensors that measure the load’s weight. The operator receives an alert from the system if the skate is overloaded.

Load limiters:

These could be physical or software systems. They must prevent the skate from operating beyond its rated capacity.

Emergency Stop Mechanisms:

Battery-powered machine skates must have reliable emergency stop systems in place. These systems ensure that the skaters can stop the skates at once in a malfunction or panic. Features to include are:

Remote emergency stop:

This allows the operator to stop the machine from a distance in case they are not near the skate.

Emergency manual override:

If the system fails, the operator should manually stop the skate using a mechanical or hydraulic system….

Collision Detection and Avoidance:

Collision detection systems are a must. They protect the equipment and operator from accidents. These systems should include:

Proximity sensors:

These can detect obstacles or moving objects in the machine’s path. They will trigger an automatic stop or rerouting mechanism.

Cameras and alarms:

Visual and auditory alerts can assist operators in identifying potential hazards.

Battery and Electrical Safety:

These skates run on battery power, so electrical safety is crucial. Key components include:

Battery monitoring systems:

To ensure that the battery doesn’t overcharge, over-discharge, or experience short circuits.

Waterproofing and insulation:

To protect electrical components from moisture, dust, and other environmental factors.

Circuit breakers and fuses:

They can prevent electrical overload and short circuits. This protects the battery and the other components.

Operator Training and Safety Guidelines:

No matter how advanced the safety features, operator training is essential. Train operators on:

- How to load and unload the machine skates without risk.

- The proper procedure for emergency stops.

- How to operate the skates under various conditions (e.g., inclines, wet surfaces).

Design Considerations for Safety Protection Systems:

We should focus on the users and the tech details. They are key to creating a safety system for battery-powered load-moving skates.

Some of the most critical considerations are:

Ergonomics: The design must focus on user comfort and accessibility. It should have easy-to-use interfaces and controls. It must reduce the risk of operator fatigue or confusion.

Redundancy:

Multiple safety features should be in place so that if one system fails, others can take over. This is particularly important for critical systems like emergency stops.

Durability:

The protection systems must be strong enough to withstand harsh industrial environments. They will face dust, moisture, and heavy impacts.

For high-quality, battery-powered machine skates, check out https://cargotrolley.com/. They have durable, reliable options designed with safety in mind.

Conclusion:

A safety system for battery-powered load-moving skates is vital. It ensures the safe and efficient movement of heavy loads. A good safety system can reduce risks. These include load instability, electrical failures, and operator injuries. Manufacturers can make the workplace safer for workers and machines. Enhance safety through load stabilization, overload safeguards, emergency halts, and collision prevention measures.