The VMC market has grown in recent years. This is due to a rising demand for precision manufacturing. It’s needed in industries like automotive, aerospace, electronics, and metalworking. As industries evolve, the need for better machines has surged. They must advance, be accurate, be fast, and be versatile. This has led to a significant rise in the use of vertical machining centers. They are now key to modern manufacturing.

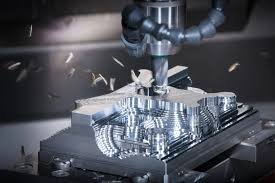

What is a Vertical Machining Center (VMC)?

A vertical machining center (VMC) is a type of CNC machine. It uses a spindle positioned in a vertical orientation to machine parts. The machine’s design allows for efficient cutting, drilling, and milling. It is often used to create complex shapes and precision parts. The VMC is versatile. It can handle many materials, from metals to plastics. Thus, it is suitable for many manufacturing applications.

Key Drivers of VMC Market Growth:

- Advanced CNC systems have made significant improvements to VMCs, or vertical machining centers. VMCs now offer greater speed, precision, and versatility. They help businesses meet stricter quality standards and make more complex parts.

- Industry 4.0 and Automation: The rise of Industry 4.0 has increased the demand for VMCs. Businesses want to automate their production lines. Vertical machining centers can fit into smart manufacturing systems. They reduce human intervention and boost efficiency.

- Customization and Versatility: Modern VMCs can perform many precise operations. So, they are ideal for custom parts. These machines are flexible. They support industries from small businesses to large manufacturers.

- Cost-Effectiveness and Global Reach: Advances in manufacturing have made VMCs cheaper. Their price is now more competitive. Chinese CNC machines, like those made by Boruimc, are gaining popularity worldwide. They are cheap and reliable.

Role of Vertical Machining Center Manufacturers:

Choosing the right vertical machining center manufacturer is vital. It ensures the machinery’s longevity and quality. Top manufacturers use precision engineering and advanced technology. They make CNC vertical machining centers for modern industries. Top companies in this field aim to deliver reliable machines. They also want high performance, enhanced by smart features. These include automatic tool changers, advanced cooling systems, and precise feedback loops.

One well-known vertical machining center manufacturer is Borui. People know Borui for its high-performance CNC vertical machining centers. Their machines blend modern technology with robust engineering. These machines meet diverse machining needs. They give industries a competitive edge.

.

Why opt for a Chinese CNC machine?

China is now a major player in global manufacturing. It makes a large share of CNC machines, including vertical machining centers. The Chinese CNC machine market has several advantages. It is cheap. It has advanced technology. It offers many machines for different production needs. Many Chinese manufacturers now make high-quality CNC machines. They compete with the best in the world. So, they are a great option for businesses seeking to expand their manufacturing at a lower cost.

Chinese CNC machines, especially vertical machining centers, have competitive prices. Their after-sales service is reliable. So, global manufacturers are choosing them more often.

FAQs:

How do Chinese CNC machines contribute to the vertical machining center market?

Chinese CNC machines, including those from Boruimc, now rank high in the global VMC market. These machines are cost-efficient. They are a good choice for small to medium businesses. They want to boost production without a big investment. Despite their competitive pricing, these machines do not compromise on quality or precision. They have advanced features, like multi-axis capabilities and high-speed performance. They help manufacturers worldwide meet rising production demands while staying affordable.

What are the benefits of a vertical machining center for SMEs?

For SMEs, investing in a vertical machining center (VMC) offers many benefits. VMCs offer high precision and versatility. They let small businesses make custom components for various industries. VMCs are adaptable. They can do small-batch production runs while ensuring quality. Also, VMCs often integrate into automated systems. This helps SMEs cut costs and improve efficiency. Manufacturers like Boruimc meet these needs. They offer affordable, high-quality CNC machines. They are for businesses that want to boost output without losing quality.

How do vertical machining centers improve the precision and efficiency of manufacturing?

Manufacturers prize vertical machining centers (VMCs) for their precision. They can perform intricate operations. This is vital for the aerospace, medical, and electronics industries. VMCs use multi-axis control systems. They can operate on parts from different angles, minimizing manual repositioning. This results in faster production times and higher consistency in the finished product. Also, VMCs have automated tool changers and cooling systems. They reduce wear on tools, improving efficiency and lifespan. The machines’ ability to do many tasks with little human help boosts productivity. This is vital in high-demand manufacturing.

What is the impact of vertical machining centers on reducing manufacturing costs?

Vertical machining centers cut costs by improving efficiency and accuracy. Their automated features, like tool changers and settings, cut costs. They speed up production runs. VMCs can do many tasks, like milling, drilling, and tapping. They do not need separate machines. This saves floor space and cuts equipment costs. VMCs’ high precision means minimal waste and fewer defects. This saves on raw materials. Manufacturers can now make high-quality products at lower costs. So, VMCs are a cost-effective investment for businesses of all sizes.