In the field of structural engineering and construction, precision is paramount. Professionals strive for accuracy in every aspect of project execution, from design to installation. One of the critical components in this process is the use of highly specific materials such as Ige Filetée zn 5.8 and HDG 5.8 M24 x 210. These components hold significant importance for ensuring structural integrity and longevity. This article will explore the ins and outs of these materials, their standards, applications, and future prospects.

What Are Ige Filetée zn 5.8 and HDG 5.8 M24 x 210?

Ige Filetée zn 5.8 and HDG 5.8 M24 x 210 are specialized threaded rods used predominantly in structural engineering and metalworking. The “zn” denotes zinc plating, which provides corrosion resistance, while “HDG” refers to hot-dip galvanization, a process that offers enhanced protection against environmental elements. These components are crucial in construction projects requiring robust and durable solutions.

The designation “5.8” indicates the strength grade of the material, signifying a balance between tensile strength and flexibility, making them suitable for various structural applications. The M24 x 210 specifies the dimensions of the rod, with M24 representing the nominal diameter and 210 indicating the length in millimeters.

The Role of Accurate Measurements in Structural Engineering

Precision in measurement is a non-negotiable requirement in structural engineering and construction. Accurate dimensions ensure the correct fit and alignment of components, which is vital for the safety and functionality of structures. Errors in measurement can lead to structural failures, costly rework, and even catastrophic accidents.

For Ige Filetée zn 5.8 and HDG 5.8 M24 x 210, precise measurement is essential to maintain the integrity of the bolted connections they form. These connections often bear significant loads, and any discrepancies can compromise the entire structure. Therefore, using advanced tools and techniques to achieve accuracy is a standard practice among industry professionals.

Standards and Specifications for Ige Filetée zn 5.8 / HDG 5.8 M24 x 210

Adhering to established standards and specifications is crucial for ensuring the quality and performance of structural components. For Ige Filetée zn 5.8 and HDG 5.8 M24 x 210, several international and local standards apply, including those set by the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM).

These standards dictate the mechanical properties, chemical composition, and coating thickness required for these components. Compliance with these standards ensures that the materials will perform as expected under various conditions, providing consistent quality and reliability for construction projects.

Manufacturing and Quality Assurance of Ige Filetée zn 5.8 / HDG 5.8 M24 x 210

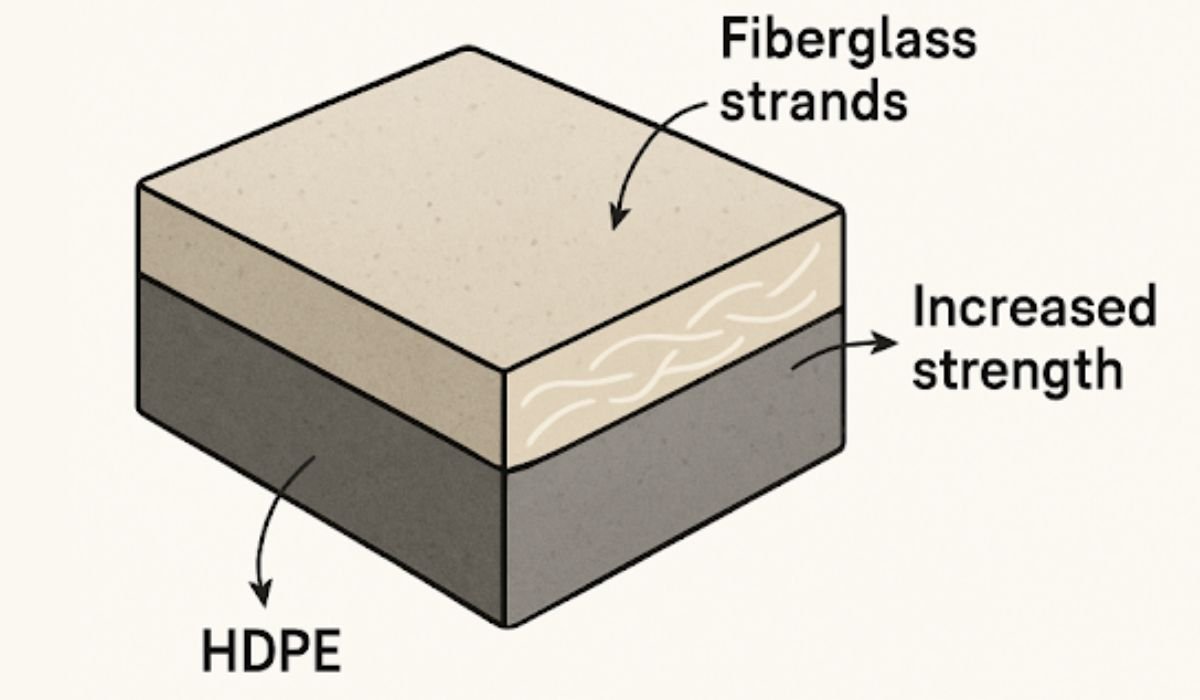

The production of Ige Filetée zn 5.8 and HDG 5.8 M24 x 210 involves several meticulous steps to ensure the highest quality. The process begins with the selection of raw materials that meet stringent specifications. These materials undergo forming, threading, and plating through zinc or hot-dip galvanization, depending on the intended application.

Quality assurance plays a pivotal role in this process. Each batch of products undergoes rigorous testing, including tensile strength tests, coating adhesion tests, and dimensional inspections. These tests ensure that the final product can withstand the demanding conditions of structural applications, offering peace of mind to engineers and construction professionals.

Applications in Construction and Metalworking

Ige Filetée zn 5.8 and HDG 5.8 M24 x 210 are widely used in various construction and metalworking applications. They are essential for creating secure connections in steel structures, anchoring systems, and heavy-duty machinery. Their ability to resist corrosion makes them ideal for outdoor and marine environments.

One notable project that utilized these components is the construction of a large-scale bridge, where their high strength and corrosion resistance were critical for the stability and longevity of the structure. Such projects highlight the importance of selecting the right materials to meet specific engineering challenges.

Considerations for Selection and Installation

Selecting the appropriate Ige Filetée zn 5.8 and HDG 5.8 M24 x 210 for a project involves several considerations. Engineers must evaluate the load requirements, environmental conditions, and compatibility with other structural elements. Choosing the correct strength grade and coating is essential to ensure optimal performance and safety.

Proper installation is equally important. Following best practices, such as using calibrated tools and adhering to torque specifications, ensures that the connections are secure and reliable. Regular inspections and maintenance further enhance the longevity of these components, preventing potential failures.

Future Trends and Innovations in Structural Engineering Materials

The field of structural engineering is continually evolving, with new technologies and materials emerging to address the industry’s challenges. Innovations such as advanced coating techniques and the development of high-performance alloys are poised to enhance the properties of materials like Ige Filetée zn 5.8 and HDG 5.8 M24 x 210.

Additionally, the integration of smart technology in construction materials is gaining traction. Sensors embedded in these components could provide real-time data on structural health, enabling proactive maintenance and reducing downtime. As these trends unfold, they will undoubtedly impact the way engineers and construction professionals approach material selection and project execution.

You May Also Like: Exploring smartthings strongman-regional.api.smartthings.com/endpointapp/init

Conclusion

In conclusion, Ige Filetée zn 5.8 and HDG 5.8 M24 x 210 are indispensable components in structural engineering and construction. Their precision, strength, and corrosion resistance make them ideal for a wide range of applications. By adhering to standards, ensuring quality, and staying informed about industry trends, professionals can optimize their use of these materials for enhanced performance and safety.

As you continue to explore the possibilities offered by these components, consider partnering with experts who can provide tailored advice and solutions. With the right approach, you can harness the full potential of Ige Filetée zn 5.8 and HDG 5.8 M24 x 210 to elevate your projects to new heights.

Frequently Asked Questions

What are the main uses of Ige Filetée zn 5.8 and HDG 5.8 M24 x 210?

These components are primarily used in structural engineering and metalworking for creating secure connections in steel structures, anchoring systems, and heavy machinery.

What does the ‘5.8’ in Ige Filetée zn 5.8 signify?

The “5.8” denotes the strength grade of the material, indicating a balance between tensile strength and flexibility suitable for various applications.

How does hot-dip galvanization (HDG) enhance these components?

Hot-dip galvanization provides enhanced protection against environmental elements, significantly improving the corrosion resistance of the components.

Why is accurate measurement crucial for these components?

Precise measurement ensures correct fit and alignment, which is vital for the safety and functionality of structures, preventing failures and costly rework.

What future innovations may impact the use of these materials?

Emerging technologies, such as advanced coatings and smart technology integration, could enhance the properties and monitoring capabilities of these components.