The drive toward cleaner, safer, and more efficient manufacturing environments has made industrial dust collection systems integral in modern operations. Technological breakthroughs are transforming how facilities handle airborne particles, with improvements that benefit both workers and operational efficiency. Key advancements focus on smarter controls, improved filtration, and energy conservation, while remaining mindful of stringent regulations.

As industries evolve, so do the tools required to maintain productivity and safety on the factory floor. Leading vendors and solution providers, such as Airblast AFC Media Blast, are responding with systems that emphasize both innovation and compliance. These new solutions enable manufacturers to better address health risks associated with airborne dust and improve day-to-day operations.

The convergence of digital monitoring, evolving filtration methods, and sustainability initiatives is rapidly modernizing the industrial dust collection sector. This momentum is not only improving internal working environments but is also critical to meeting the increasingly stringent standards set by governmental agencies and local authorities. The impact is significant in industries where hazardous or combustible dusts are present, bolstering safety and peace of mind for workers and managers alike.

Integrating these systems with broader facility controls enables companies to measure, predict, and optimize dust management more easily. Automated alerts, predictive maintenance, and energy-saving configurations have moved dust collection from a background function to a strategic asset within manufacturing operations.

Smart Monitoring and Control

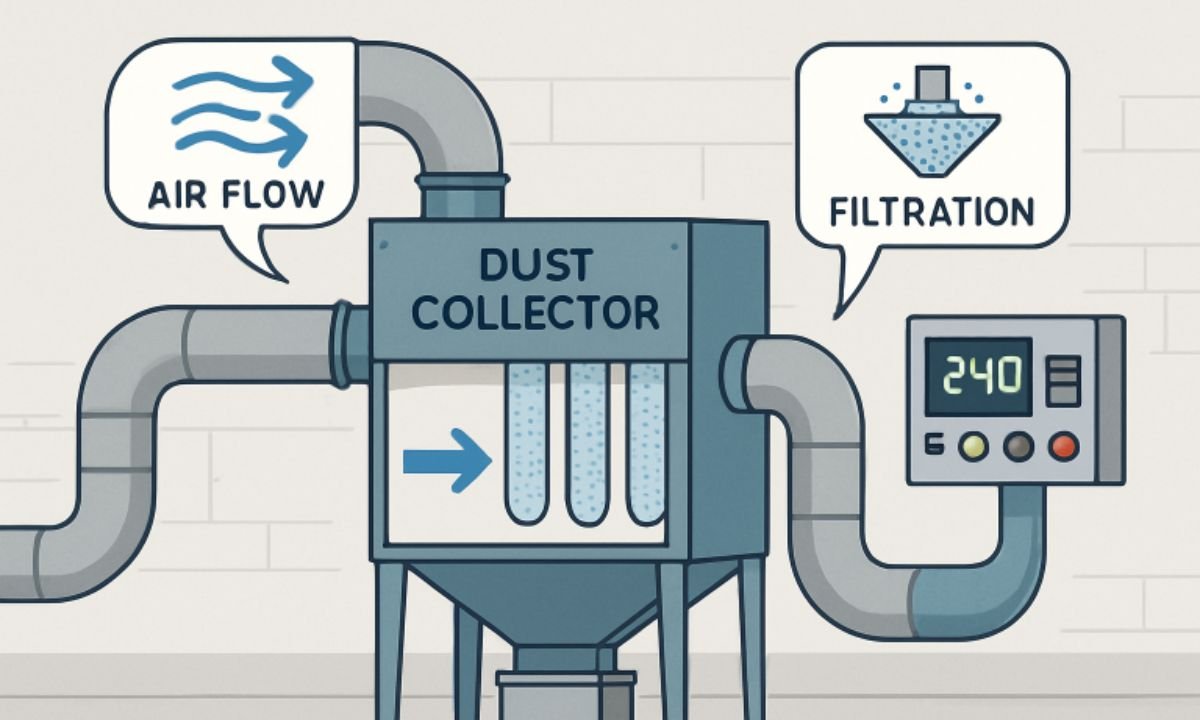

Modern dust collection systems now feature embedded sensors, Human-Machine Interface (HMI) touch panels, and SCADA controls. These systems are designed to provide operators with real-time insights into airflow rates, pressure drops, and filter health, enabling proactive maintenance and early detection of issues. By leveraging advanced algorithms, smart controls can automatically adjust critical parameters to maintain optimal performance and reduce downtime. According to Processing Magazine, these innovative systems can be tailored for diverse production setups and scaled for small workshops or expansive multi-site installations. As a result, plants are now better equipped to balance productivity with safe working conditions.

Advanced Filtration Technologies

Filter performance is critical in effective dust extraction. Advances in media composition and filter design have led to pulse-cleaned cartridge technologies that use short bursts of compressed air to dislodge particulate buildup without significantly impeding airflow. This self-cleaning method prolongs filter life and helps keep maintenance costs low. The use of nanofiber and pleated filter media enables higher efficiency in trapping even the smallest dust particles, minimizing hazardous exposures. Larger manufacturers and new market entrants alike are adopting these breakthroughs, responding to industries where even minute particulate levels can have outsized impacts on health and productivity.

Energy-Efficient Designs

Energy consumption is a significant operational concern in dust collection, particularly in facilities with multiple extraction lines or large-scale filtration banks. Companies like Ecogate have introduced systems that dynamically adjust fan speeds and power consumption in response to real-time demand from various workstations. Ecogate’s On-Demand Control System has demonstrated the ability to reduce electricity use by up to 68 percent, a leap forward in resource conservation for energy-intensive industries. These systems support sustainability initiatives and provide measurable reductions in operational costs, helping manufacturers meet both environmental benchmarks and budgetary constraints.

Eco-Friendly Dust Suppression

In addition to mechanical filtration, some applications require dust-suppressing fluids to minimize airborne dust, particularly in outdoor or sensitive environments such as mines and remediation sites. Recent innovations have produced biodegradable formulations that do not leave harmful residues, mitigating the ecological risks traditionally associated with chemical suppressants. These advancements allow companies to maintain compliance with environmental standards while protecting local habitats and water sources from contamination. The trend towards greener alternatives underscores the industry’s commitment to responsible manufacturing and environmental stewardship.

For more insight on how these innovations are driving change, visit this EPA resource on air quality and pollution control.

Integration with IoT

The Industrial Internet of Things (IoT) has further propelled dust collection systems into the realm of smart facility management. By integrating wireless sensors and innovative averaging artificial intelligence platforms, facilities now gain continuous visibility into their dust collection operations. Predictive analytics enable facility managers to anticipate filter clogs and plan maintenance before critical failures occur. Automation of compliance reporting is another benefit, streamlining documentation for audits and facilitating faster response to regulatory queries. These digital platforms drive cleaner air and lower costs, while maximizing uptime and labor efficiency.

Compliance with Regulations

Regulatory compliance is non-negotiable for industries generating any form of airborne dust. Agencies like OSHA and standards set by the Clean Air Act require diligent management of particles to prevent occupational diseases and mitigate fire or explosion risks. Advanced dust collection systems simplify compliance by automating emissions monitoring and record keeping. Effective dust management also contributes to improved employee morale and reduced liability, while reinforcing the company’s commitment to sustainable and responsible operations. As legislation and industry standards evolve, upgrading to intelligent dust collection solutions ensures ongoing adherence and prepares companies for future operational challenges.

For comprehensive guidance on industrial safety regulations, reference OSHA’s dust hazard guidelines.

Conclusion

The convergence of smart technology, advanced engineering, and environmental coinnovativeusness marks the evolution of industrial dust collection, efficient while maintaining regulatory compliance and meeting sustainability goals. By embracing next-generation monitoring, energy-saving designs, and eco-friendly dust suppression, forward-thinking facilities can build robust, future-ready dust management strategies that maximize productivity and protect what matters most.

Read Also: How Immediate X2 ProAir Transforms Your Home Air from Stale to Sanctuary