The industrial sector faces continuous pressure to adapt and innovate supply solutions as technology and customer expectations advance. As businesses strive to keep up with rapid market shifts, embracing new strategies in supply management has become essential to stay competitive. Incorporating streamlined processes, innovative technologies, and sustainable initiatives ensures not only resilience and efficiency but also positions businesses for future growth and success.

Manufacturers and suppliers, such as Cruco Mill & Industrial Supply North Carolina, are at the forefront of this evolution, integrating both global innovations and region-specific best practices to enhance the performance of supply chains. With increased competition and demand for transparency, the industrial supply sector is witnessing a surge in groundbreaking approaches to logistics, inventory management, and supplier relations.

Automation, AI-driven analytics, and smart connected devices are all transforming traditional supply models. By embedding these advanced systems, businesses can efficiently manage risks, enhance accuracy, and develop adaptable frameworks that better weather disruptions. Concurrently, enhanced transparency practices, data-driven decisions, and eco-friendly solutions are becoming pillars of modern supply chains.

Combining technology adoption, operational efficiency, and sustainable commitments ensures that suppliers and manufacturers can meet both market needs and regulatory requirements. This approach not only strengthens supply chains but also builds greater trust with partners and customers alike.

Embracing Automation and Robotics

Innovations in automation are revolutionizing industrial supply movements. Autonomous Mobile Robots (AMRs) and collaborative robots (cobots) now perform repetitive or hazardous tasks within warehouses, reducing human errors while allowing workers to focus on higher-level responsibilities. Material handling robots, such as those by Peppermint Robotics, exemplify how robotics boost accuracy and expedite order fulfillment processes. These robotics seamlessly integrate with inventory systems, multiplying workflow capacity without compromising safety or flexibility. According to Forbes, automation now defines competitive warehouse operations by shortening lead times and reducing overhead.

Leveraging Artificial Intelligence for Resilient Supply Chains

Artificial Intelligence is at the heart of next-generation supply chain management strategies. Using high-powered algorithms and real-time data analytics, AI platforms forecast demand patterns, resolve logistical bottlenecks, and flag potential disruptions before they escalate. AI-driven predictive maintenance minimizes unplanned downtime for essential equipment, while adaptive algorithms optimize route planning and resource allocation. Recent research by McKinsey shows that businesses leveraging AI outpace their peers in agility and responsiveness, crucial traits in unpredictable market environments.

Implementing Blockchain for Transparency and Traceability

Blockchain technology is rapidly reshaping how companies share and authenticate transactional data within supply networks. Unlike traditional ledgers, blockchain secures data on an immutable and decentralized platform, drastically reducing fraud, facilitating compliance, and simplifying recalls or audits. Its use is particularly transformative in industries where documentation of product origin and chain of custody is critical, such as the food and pharmaceutical sectors. Blockchain adoption is also helping businesses align with evolving regulatory standards and customer expectations for complete transparency across their entire supply chain.

Integrating IoT for Real-Time Monitoring

The Internet of Things, through tools such as RFID, GPS trackers, and environmental sensors, delivers unparalleled real-time insights into product location, ambient conditions, and equipment performance. This visibility enables dynamic inventory management and proactive maintenance, cutting both waste and unexpected costs. IoT-connected assets generate actionable data streams, enabling supply specialists to identify inefficiencies or respond to deviations quickly. These benefits are not just technical—precise, up-to-date information empowers stronger decision-making and tighter inventory controls.

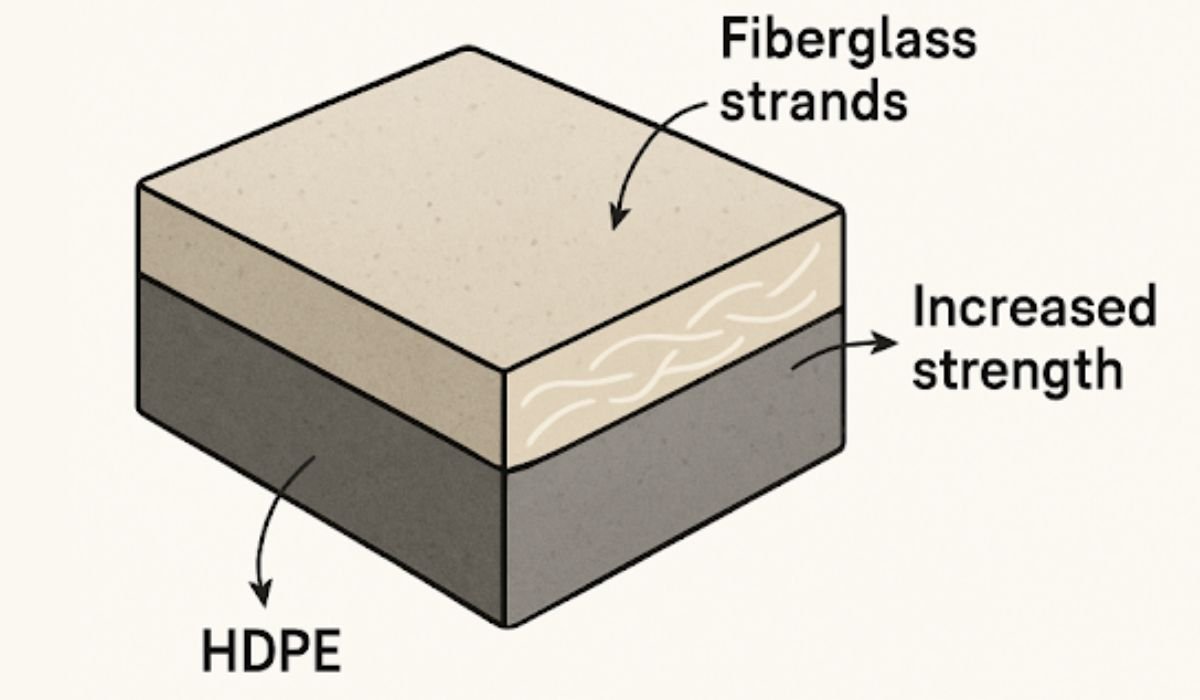

Adopting Sustainable Practices

Environmentally conscious operations are increasingly integral to industrial supply solutions. Businesses are not only optimizing delivery routes to lower emissions but are also switching to eco-friendly packaging and recycled materials. The integration of circular economy principles, such as reusing or remanufacturing components, reduces resource consumption and appeals to a growing segment of environmentally conscious customers. Companies are actively prioritizing partners with sustainable certifications or demonstrated reductions in carbon footprints to support broader environmental goals.

Enhancing Cybersecurity Measures

Strengthening cybersecurity has become non-negotiable for supply chains operating in an interconnected world. As digital transformation accelerates, so do the threats targeting sensitive operational and client information. Businesses are thus enforcing comprehensive encryption standards, ongoing vulnerability assessments, and dedicated employee training on security best practices. Strong security frameworks ensure supply chain continuity, trust, and regulatory compliance while mitigating the risk of costly breaches.

Fostering Supplier Collaboration

Deep collaboration with suppliers lays the groundwork for resilient and innovative supply chains. Digital management platforms offer seamless communication, reliable data sharing, and joint forecasting. Establishing long-term partnerships allows for mutually beneficial planning, shared risk management, and innovations tailored to industry trends. This cooperative mindset not only improves supply chain flexibility but also builds strong strategic alliances for future growth.

Conclusion

Cutting-edge approaches to industrial supply solutions are essential for businesses seeking operational excellence in a volatile world. By adopting automation, AI, blockchain, IoT, sustainable methodologies, advanced cybersecurity, and robust supplier collaboration, companies can build leaner, more adaptive, and future-proof supply chains. These strategies enable firms to deliver greater customer value, meet stringent compliance criteria, and enhance their overall competitiveness in the industrial arena.

YOU MAY ALSO LIKE: How EC Fans and Drives Improve Efficiency in Industrial Air Management