Excavation work is at the core of construction and infrastructure projects, with its complexity stemming not only from technical demands but also from critical safety challenges. Utility strikes and trench collapses remain major risks, underscoring the industry’s need to prioritize innovation. New technologies and methods are transforming how contractors approach these issues, ensuring safer working environments and more reliable project timelines. For contractors seeking established expertise and local solutions, exploring full excavations Festus, MO, can provide trusted insight and support for modern excavation requirements.

Integrating innovation is essential for keeping workers safe and projects on track. Today, the adoption of digital tools, automation, and environmentally conscious solutions is helping the excavation industry reach new heights in operational safety and sustainability. These advancements not only lower the risk of accidents but also enhance productivity, giving operations a competitive edge and building trust with communities and clients.

One of the most remarkable changes in excavation is the move toward smart management platforms and precision gear. Together, these tools reshape how excavation sites are planned and managed, aligning safety, productivity, and compliance from the ground up. Establishing a robust safety framework starts with proactive hazard detection, comprehensive worker training, and environmentally sound practices.

Real-Time Utility Detection Systems

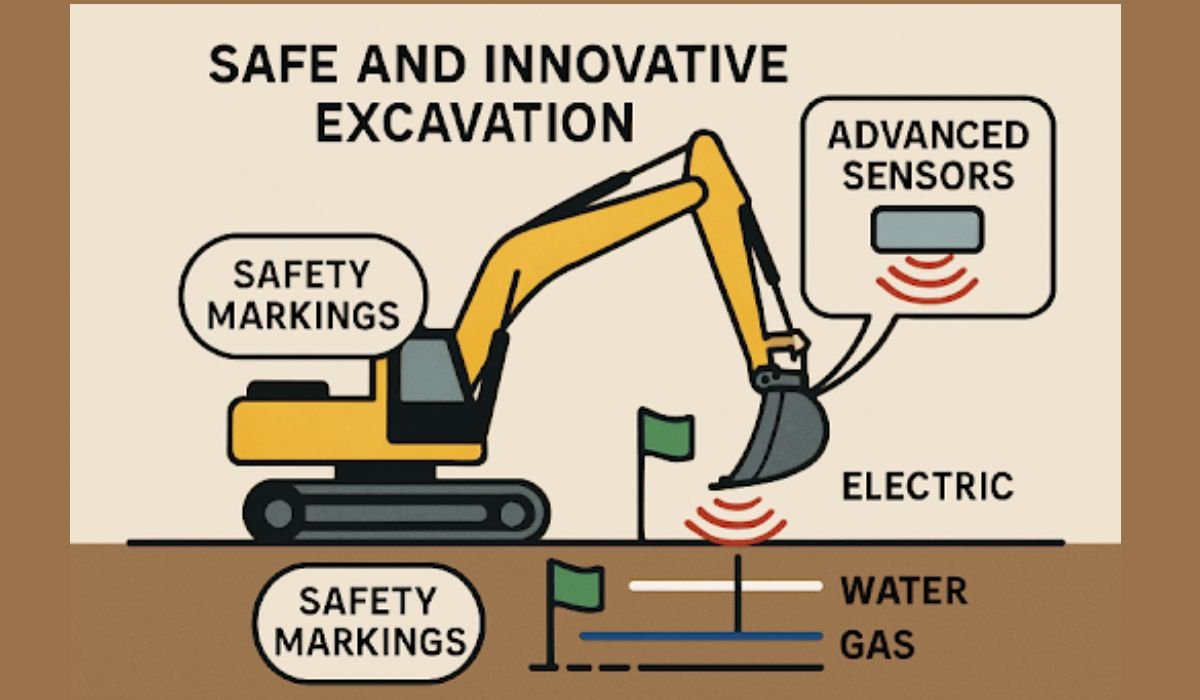

Utility strikes can lead to costly delays, injuries, and service disruptions. Real-time utility detection technologies, such as ground-penetrating radar (GPR), provide essential visibility below the surface. This proactive approach allows operators to accurately locate and avoid underground utilities. By leveraging these systems, operators increase accuracy and protect essential services, thereby improving site safety and company reputation. According to the Occupational Safety and Health Administration (OSHA), proper utility identification is a cornerstone of safe excavation practices.

Autonomous Excavation Equipment

Robotics and automation are increasingly playing a major role in construction. Autonomous excavators, equipped with sensors and guided by artificial intelligence, can perform tasks with minimal human intervention. This technology is especially valuable for tasks in hazardous or tight locations, where manual work poses greater dangers. Recent research has shown that these smart machines can complete complex digging cycles with centimeter-level precision, reducing operator fatigue and human error. Enhanced reliability leads to shorter project timelines and fewer workplace injuries.

Comprehensive Safety Training Programs

Training remains a fundamental pillar for excavation site safety. Comprehensive programs, such as United Rentals’ Excavation Safety Training for Competent Persons, integrate theoretical concepts with hands-on exercises. These curricula cover key topics, including site hazard identification, soil evaluation, and the use of protective systems such as trench boxes and shoring. Engaging, interactive training ensures that workers remain alert to evolving hazards and regulatory frameworks, raising overall site safety and boosting productivity. These investments in workforce development create a safety-conscious culture and reduce incident rates over time.

Eco-Friendly Excavation Practices

As awareness of environmental stewardship grows, the excavation industry is prioritizing sustainable methods to reduce ecological impact. The use of electric and hybrid excavators is on the rise, significantly lowering emissions on active job sites. Innovative soil stabilization techniques, such as geotextiles, help minimize erosion and maintain soil health. Recycling excavated materials and adopting responsible waste management practices contribute to more sustainable project outcomes. These eco-friendly measures not only meet regulatory requirements but also enhance project value for contractors and the communities they serve.

Utilizing Vacuum Excavators

Vacuum excavation equipment offers a precise, non-destructive alternative for exposing and working around underground utilities. Using suction to safely remove soil, this approach minimizes the risk of accidental damage to cables and pipelines. Manufacturers like Vermeer are innovating with advanced features and ergonomic designs that further enhance safe digging practices. Vacuum excavators are particularly valuable in congested urban areas and environmentally sensitive projects, allowing crews to achieve surgical precision while maintaining regulatory compliance and site safety.

Implementing Smart Site Management Systems

Modern excavation projects benefit greatly from smart site management systems that utilize real-time data collection, analytics, and machine learning. These platforms monitor equipment performance, track project milestones, and detect potential hazards before they escalate. Integrated dashboards help managers allocate resources effectively, ensure compliance, and quickly adapt to changing site conditions. Enhanced visibility and decision-making not only reduce risk but also keep projects on schedule and within budget, reinforcing the value of adopting these digital innovations across the industry.

Final Thoughts

The future of excavation is firmly rooted in innovation and safety-first thinking. By adopting real-time utility detection, autonomous equipment, robust safety training, sustainable practices, vacuum excavation, and advanced management systems, the construction industry is well-positioned to mitigate risks and improve overall project quality. As technology evolves, these solutions will continue to drive progress, setting a new benchmark for safe and effective excavation practices.

YOU MAY ALSO LIKE: A Construction Essential: The Role of Skid Steer Loaders