The electric vehicle (EV) industry is booming, and with this surge comes the need for robust standards that ensure safety, efficiency, and innovation. One such pivotal standard is China’s QC/T 1037-2016. This guideline plays a crucial role in shaping how EV cables are designed, manufactured, and implemented across vehicles, impacting not just China but the global market as well. Let’s explore how QC/T 1037-2016 is revolutionizing the EV landscape.

Introduction to QC/T 1037-2016

QC/T 1037-2016 is a comprehensive industry standard focusing on electric vehicle cables. It outlines specific requirements and testing methods that manufacturers must follow to ensure product quality and performance.

Understanding the nuances of the QC/T 1037-2016 standard is essential for automotive engineers, electric vehicle enthusiasts, and sustainable technology innovators. By regulating the production and implementation of EV cables, this standard helps foster a safer and more efficient electric vehicle market.

The standard’s significance lies in its ability to enhance the reliability and efficiency of electric vehicles. By setting high benchmarks for cable quality, QC/T 1037-2016 ensures that EVs can operate safely under various conditions, thereby boosting consumer confidence in this sustainable mode of transportation.

Understanding QC/T 1037-2016

Objectives and Scope of QC/T 1037-2016

The primary objective of QC/T 1037-2016 is to standardize the design and manufacturing processes for electric vehicle cables. This ensures that all products meet a consistent level of performance and safety across the industry.

The scope of the standard covers various aspects of cable production, including materials used, mechanical properties, and environmental resistance. It aims to provide comprehensive guidelines that manufacturers and engineers can rely on when developing new products or refining existing ones.

The technical requirements outlined in QC/T 1037-2016 serve as a blueprint for creating EV cables that are not only durable but also efficient. From tensile strength to thermal resistance, each criterion is carefully designed to ensure optimal performance in real-world applications.

Technical Requirements and Testing Methods

QC/T 1037-2016 specifies a range of technical requirements that EV cables must adhere to. These include crucial factors such as electrical conductivity, insulation resistance, and temperature tolerance.

Testing methods are integral to the standard, as they provide an objective means of assessing whether a product meets the established criteria. Common tests include mechanical endurance tests, electrical performance assessments, and environmental stress evaluations.

By implementing rigorous testing protocols, QC/T 1037-2016 ensures that all EV cables are capable of withstanding the demands of modern electric vehicles. This not only enhances the longevity of the cables but also contributes to the overall reliability of the vehicles they power.

Impact on Electric Vehicle Technology

Influence on EV Cable Design and Production

The introduction of QC/T 1037-2016 has significantly influenced the design and production of electric vehicle cables. Manufacturers are now prioritizing innovation and quality, ensuring their products meet the standard’s stringent requirements.

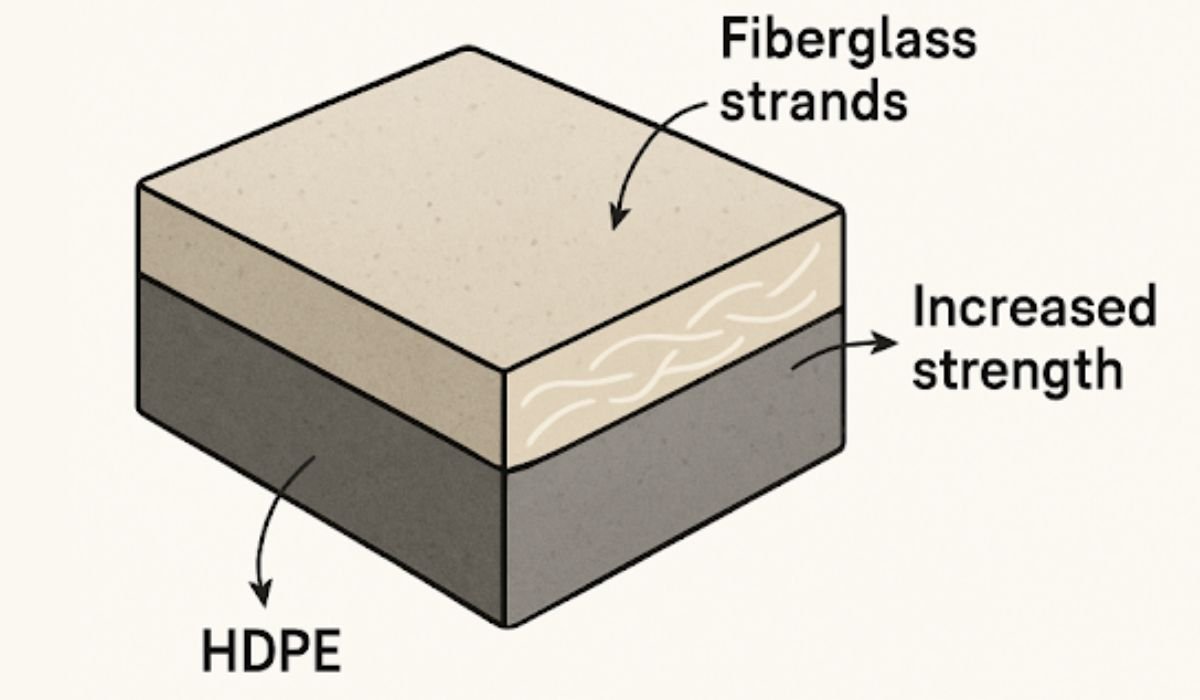

This focus on quality has led to the development of more efficient and reliable EV cables, which are better equipped to handle the unique demands of electric vehicles. From improved insulation materials to enhanced thermal management, these advancements are paving the way for a new era of electric mobility.

By adhering to QC/T 1037-2016, manufacturers can produce cables that not only meet regulatory standards but also exceed customer expectations. This has resulted in increased consumer confidence and greater adoption of electric vehicles worldwide.

Advancing Safety and Efficiency in EVs

One of the key benefits of QC/T 1037-2016 is its focus on enhancing safety and efficiency within the electric vehicle sector. By establishing clear guidelines for cable design and testing, the standard ensures that all products can perform reliably under various conditions.

Improved safety measures include enhanced insulation materials and robust mechanical properties, which reduce the risk of electrical failures or fires. These advancements have made electric vehicles a more attractive option for consumers, contributing to their growing popularity.

In addition to safety, QC/T 1037-2016 also promotes efficiency by encouraging manufacturers to develop cables that minimize energy loss and maximize performance. This focus on efficiency helps to extend the range of electric vehicles, making them a more practical choice for everyday use.

Adoption and Compliance

How Manufacturers are Adopting the Standard

Many manufacturers are adopting QC/T 1037-2016 to ensure their products meet the highest standards of quality and performance. By following the guidelines set forth in the standard, they can produce cables that are not only compliant but also competitive in the global market.

Compliance with QC/T 1037-2016 involves rigorous testing and quality control measures, which help manufacturers identify and address potential issues before they reach consumers. This proactive approach to product development ensures a high level of reliability and customer satisfaction.

Manufacturers who successfully implement QC/T 1037-2016 can gain a competitive edge in the electric vehicle market, as their products are recognized for their superior quality and performance. This recognition can lead to increased sales and greater brand loyalty among consumers.

Challenges and Benefits of Compliance

While compliance with QC/T 1037-2016 offers numerous benefits, it also presents certain challenges for manufacturers and engineers. These may include the need for advanced testing equipment, updated production processes, and ongoing staff training.

Despite these challenges, the benefits of compliance far outweigh the costs. By meeting the standard’s requirements, manufacturers can produce cables that are safer, more efficient, and more reliable than their competitors. This can lead to increased market share and brand recognition.

Furthermore, compliance with QC/T 1037-2016 demonstrates a commitment to quality and innovation, which can enhance a company’s reputation within the industry. This positive reputation can attract new customers and foster long-term relationships with existing clients.

Global Implications and Future Trends

Influence Beyond China’s Borders

The impact of QC/T 1037-2016 extends beyond China, influencing the global electric vehicle market and setting a benchmark for cable quality worldwide. Its comprehensive guidelines and rigorous testing methods have inspired similar standards in other countries, promoting a more unified approach to EV cable production.

By adopting QC/T 1037-2016, manufacturers can ensure their products are competitive in the international market, opening up new opportunities for growth and expansion. This global influence has helped to raise the bar for quality and innovation within the electric vehicle industry.

The standard’s success in China has prompted other countries to consider adopting similar guidelines, fostering greater collaboration and consistency within the global electric vehicle market. This increased cooperation can lead to more efficient and sustainable transportation solutions worldwide.

Future Developments and Updates

As technology continues to evolve, so too will the requirements outlined in QC/T 1037-2016. Future updates to the standard are likely to incorporate new advancements in materials science, electrical engineering, and environmental sustainability.

These updates will help to ensure that EV cables remain at the forefront of innovation, offering improved performance and reliability in an increasingly competitive market. By staying ahead of emerging trends, manufacturers can continue to develop products that meet the needs of tomorrow’s consumers.

In addition to technological advancements, future updates to QC/T 1037-2016 may also address emerging concerns related to environmental sustainability and resource conservation. By incorporating eco-friendly practices into cable production, manufacturers can contribute to a more sustainable future for the electric vehicle industry.

You May Also Like: H/C/I Modifications in Ford Mustangs Drive Unmatched Performance

Conclusion

QC/T 1037-2016 is a critical standard that has significantly influenced the design, production, and implementation of electric vehicle cables. By providing clear guidelines and rigorous testing methods, it ensures that all products meet a consistent level of quality and performance, enhancing safety and efficiency within the electric vehicle market.

For automotive engineers, electric vehicle enthusiasts, and sustainable technology innovators, understanding and adopting QC/T 1037-2016 is essential for staying ahead in an increasingly competitive industry. By following the standard’s guidelines, they can develop products that not only meet regulatory requirements but also exceed customer expectations.

As the electric vehicle market continues to grow, the importance of QC/T 1037-2016 will only increase. By staying informed about future developments and updates to the standard, manufacturers and engineers can ensure their products remain at the forefront of innovation, contributing to a more sustainable and efficient transportation future.

FAQs

What is QC/T 1037-2016?

QC/T 1037-2016 is a Chinese industry standard that sets guidelines for the design, production, and implementation of electric vehicle cables, ensuring they meet specific performance and safety requirements.

Why is QC/T 1037-2016 important for electric vehicles?

The standard enhances the safety and efficiency of electric vehicles by ensuring that cables meet stringent quality criteria, reducing the risk of electrical failures and improving overall vehicle performance.

How does QC/T 1037-2016 impact global markets?

The standard has influenced the global electric vehicle market by setting a benchmark for cable quality, inspiring similar standards in other countries and promoting a more unified approach to EV cable production.

What are the main challenges of complying with QC/T 1037-2016?

Challenges may include the need for advanced testing equipment, updated production processes, and ongoing staff training. However, the benefits of compliance, such as increased market share and brand recognition, far outweigh these challenges.

What future developments can we expect for QC/T 1037-2016?

Future updates to the standard may incorporate advancements in materials science, electrical engineering, and environmental sustainability, ensuring EV cables remain at the forefront of innovation and contribute to a more sustainable transportation future.