Are you a small business owner, graphic designer, or print shop manager who is always on the lookout for the latest advancements in printing technology? If so, this blog post is for you. Today, we’ll explore the fascinating evolution of r/DTG (Direct-to-Garment) printing technology, from its early days to its current state, and why it’s making waves in the printing industry.

In this post, we’ll cover what r/DTG printing is, its history and technological advancements, how it works, its advantages, common challenges and solutions, best practices, and its future potential. By the end, you’ll understand why r/DTG printing is a game-changer for anyone involved in the world of printing.

What is r/DTG Printing?

Brief Overview of r/DTG Technology

r/DTG printing, or Direct-to-Garment printing, is a method where digital designs are printed directly onto fabric using specialized inkjet technology. Unlike traditional screen printing, which requires separate screens for each color, r/DTG allows for full-color prints in a single pass. This makes it ideal for printing complex designs with multiple colors and gradients.

Importance in the Printing Industry

r/DTG printing has revolutionized the printing industry by offering a high-quality, versatile, and eco-friendly alternative to traditional methods. It’s especially beneficial for small businesses and print shops that want to offer customized prints without the need for large volume orders. This technology has opened up new opportunities for entrepreneurs and creatives, making it easier than ever to bring unique designs to life.

Applications in the Industry

The applications of r/DTG printing are vast. From custom t-shirts and hoodies to tote bags and hats, this technology is perfect for creating personalized products. It’s widely used in fashion, promotional products, and even in creating prototypes for new clothing lines. The ability to print on-demand means businesses can offer a wider range of products without the risk of overstocking.

History and Evolution of r/DTG Printing

Early Beginnings

The concept of Direct-to-Garment printing began in the early 1990s. The first r/DTG printers were rudimentary and limited in their capabilities. They were developed to provide an alternative to screen printing, which was time-consuming and not cost-effective for short runs. These early machines laid the groundwork for the advanced technology we have today.

Technological Advancements

Over the years, r/DTG printing technology has seen significant advancements. One of the key milestones was the introduction of white ink, which allowed for printing on dark fabrics. This was a game-changer, as it expanded the range of printable materials. Improvements in ink formulations, print head technology, and software have also contributed to the high-quality prints we see today.

Key Milestones

Several key milestones have shaped the evolution of r/DTG printing. In the early 2000s, the introduction of piezoelectric print heads improved print quality and speed. The development of more durable and vibrant inks has also played a crucial role. Today, r/DTG printers are capable of producing photo-realistic prints with incredible detail and color accuracy.

How r/DTG Printing Works

The r/DTG Process

The r/DTG printing process begins with a digital design file, typically created using graphic design software. This file is then processed by RIP (Raster Image Processor) software, which converts the design into a format that the printer can understand. The fabric is pre-treated to ensure the ink bonds properly, and then the printer applies the ink directly onto the garment in a single pass.

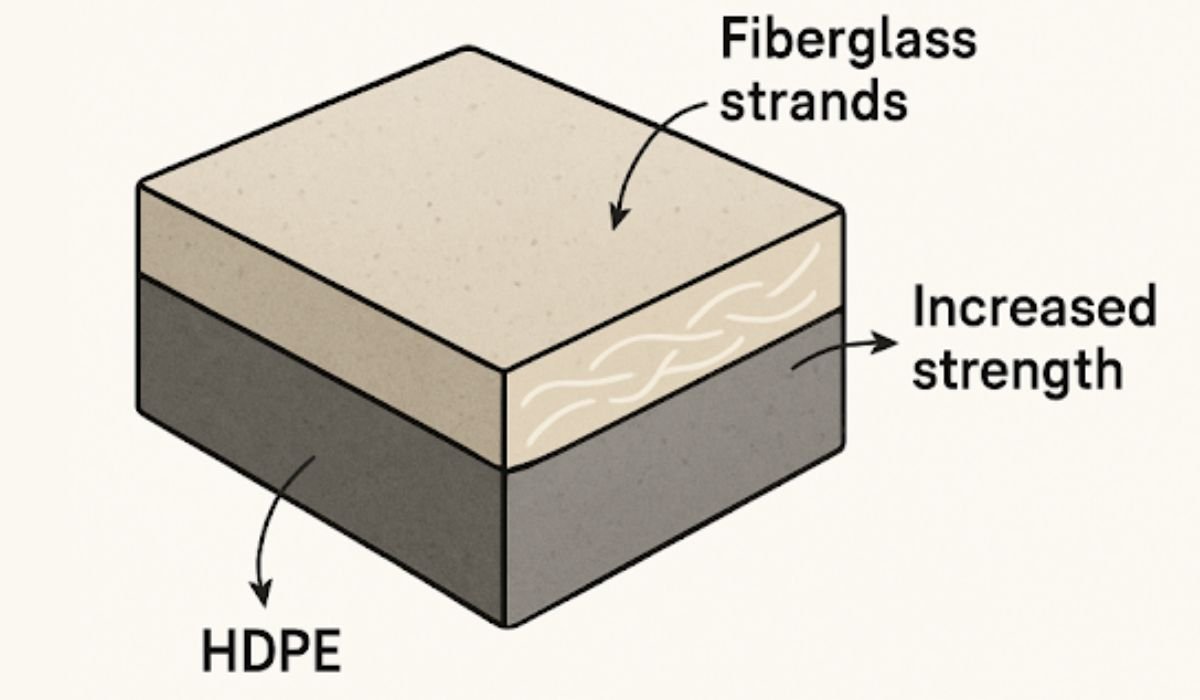

Equipment and Materials

r/DTG printing requires specialized equipment, including the printer itself, pre-treatment machines, and heat presses. The inks used are water-based and eco-friendly, designed to bond with the fabric fibers for a soft, durable finish. Various substrates can be used, including cotton, polyester, and blends, allowing for a wide range of printable products.

Step-by-Step Explanation

- Design Creation: Start with a high-resolution digital design file.

- Pre-Treatment: Apply a pre-treatment solution to the fabric to help the ink adhere properly.

- Printing: Load the fabric into the r/DTG printer and print the design directly onto it.

- Drying: Use a heat press to cure the ink and ensure it sets properly.

- Quality Check: Inspect the finished product for any defects or inconsistencies.

Advantages of r/DTG Printing

Quality and Detail

One of the standout advantages of r/DTG printing is the exceptional quality and detail it offers. The technology allows for high-resolution prints with vibrant colors and intricate details. Whether you’re printing a detailed illustration or a photo, r/DTG can handle it with ease.

Versatility

r/DTG printing is incredibly versatile, allowing you to print on a wide range of fabrics and materials. This flexibility makes it a popular choice for custom apparel, promotional products, and even home textiles. The ability to print on-demand means you can offer a diverse product range without the need for large inventory.

Eco-Friendliness

Compared to traditional printing methods, r/DTG is more environmentally friendly. The water-based inks used are non-toxic and produce less waste. Additionally, the ability to print on-demand reduces the need for large production runs, minimizing excess inventory and waste.

Common Challenges and Solutions

Technical Issues

Like any technology, r/DTG printing comes with its own set of challenges. Common issues include white outlines around designs, transparency gaps, and ink bleeding. However, these problems can often be resolved with proper printer settings and maintenance.

Maintenance and Upkeep

Keeping your r/DTG printer in good working condition is essential for consistent print quality. Regular cleaning and maintenance are crucial to prevent clogs and other issues. Following the manufacturer’s guidelines for upkeep will help ensure your printer remains in top shape.

Tips for Troubleshooting

- White Outlines: Ensure the pre-treatment is applied evenly and the fabric is correctly aligned.

- Transparency Gaps: Adjust the print settings and check the design file for any issues.

- Ink Bleeding: Use the right amount of pre-treatment and ensure the fabric is compatible with r/DTG printing.

Best Practices for r/DTG Printing

Design Tips

Creating designs optimized for r/DTG printing is key to achieving the best results. Use high-resolution images and avoid overly intricate details that may not translate well. Consider the fabric color and texture when designing, as these factors can affect the final print.

Printer Settings

Adjusting your printer settings to match the fabric and design is essential for quality prints. Experiment with different settings to find the optimal combination for each project. Keep a record of successful settings for future reference.

Quality Control

Implementing a robust quality control process ensures consistent and high-quality output. Inspect each print for defects, and make adjustments as needed. Regularly calibrate your equipment to maintain optimal performance.

Case Studies and Success Stories

Real-World Examples

Many businesses have successfully integrated r/DTG printing into their operations. For instance, a small t-shirt company used r/DTG technology to offer customized designs, resulting in increased customer satisfaction and sales. Another example is a print shop that expanded its product range by adding r/DTG services, attracting new clients and boosting revenue.

Lessons Learned

These success stories highlight the importance of understanding the technology and maintaining high standards of quality. Investing in the right equipment and training can make a significant difference in the success of your r/DTG printing endeavors.

Key Takeaways

- Understand the capabilities and limitations of r/DTG printing.

- Prioritize quality control and regular maintenance.

- Leverage the versatility of r/DTG to offer a diverse product range.

Future of r/DTG Printing

Emerging Trends

The future of r/DTG printing looks promising, with ongoing advancements in technology and materials. Innovations such as faster print speeds, improved ink formulations, and expanded fabric compatibility are on the horizon. These developments will further enhance the capabilities and appeal of r/DTG printing.

Market Potential

The market potential for r/DTG printing is vast, with increasing demand for customized and on-demand products. Small businesses, in particular, can benefit from the flexibility and cost-effectiveness of r/DTG printing. As the technology continues to evolve, new opportunities will emerge for entrepreneurs and print professionals.

Industry Forecasts

Industry experts predict continued growth in the r/DTG printing market, driven by advancements in technology and increasing consumer demand for personalized products. Staying informed about these trends and developments will help businesses stay competitive and capitalize on new opportunities.

You May Also Like: Discover the Magic of I/O Drawers in Computing

Conclusion

r/DTG printing has come a long way since its early days, evolving into a powerful and versatile technology that offers numerous benefits for small business owners, graphic designers, and print shop managers. From high-quality prints and eco-friendly practices to the ability to print on-demand, r/DTG printing is revolutionizing the printing industry.

By understanding its history, how it works, and best practices for its use, you can harness the power of r/DTG printing to enhance your business. Whether you’re looking to offer customized products, improve print quality, or expand your product range, r/DTG printing has the potential to help you achieve your goals.

Stay ahead of the curve by keeping an eye on emerging trends and developments in r/DTG technology. And if you’re ready to take your printing capabilities to the next level, consider integrating r/DTG printing into your operations.

Frequently Asked Questions

What is r/DTG printing?

r/DTG printing, short for direct-to-garment printing, is a digital printing method that applies ink directly onto fabric using specialized inkjet technology. It allows for high-quality, full-colour images and custom designs to be printed onto various garments.

What are the benefits of using r/DTG printing?

The advantages of r/DTG printing include eco-friendliness due to water-based inks, the ability to produce on-demand prints which reduces waste, lower upfront inventory costs, and the capacity to create intricate, multi-colour designs with precision.

How do I troubleshoot common r/DTG printing issues?

Common troubleshooting tips include ensuring even application of pre-treatment to eliminate white outlines, adjusting print settings and checking design files to address transparency gaps, and using the appropriate amount of pre-treatment to prevent ink bleeding.

What best practices should I follow for r/DTG printing?

To achieve optimal results, use high-resolution images, adjust printer settings according to the fabric and design, maintain consistent quality control, and conduct regular maintenance on your equipment.

What does the future hold for r/DTG printing?

The future of r/DTG printing looks bright, with emerging trends pointing toward advancements in print speeds, improved ink formulations, and greater fabric compatibility, alongside a growing market demand for customized and on-demand products. Staying informed about these developments will be crucial for businesses looking to leverage this technology.