Key Takeaways

- Understanding the basics of adhesive technologies and their widespread applications.

- The significant role adhesives play in innovative solutions across various industries.

- Environmental and sustainable advancements within adhesive production and usage.

Adhesive Technologies: More Than Just Glue

In today’s high-tech world, adhesive technologies are everywhere, quietly aiding our daily routines and industrial processes. From the tape that holds packaging together to the sophisticated bonding agents used in aerospace, the significance of adhesives cannot be overstated. They are intricate combinations of chemistry and engineering, not merely simple sticky substances. The progression in adhesive technology has allowed these materials to meet various demands across industries, including providing formidable solutions such as Construction Glue Leech Adhesives. This advancement showcases their ability to cater to complex bonding requirements, driving innovation forward and enhancing practical applications across various domains. As industries evolve, adhesives are formulated to withstand extreme temperatures, moisture exposure, and heavy mechanical stress, ensuring durability and reliability. Their role in sustainable development is also expanding, with eco-friendly and biodegradable adhesives reducing environmental impact without compromising performance. With ongoing research and technological advancements, the future of adhesives promises even greater versatility, efficiency, and integration into cutting-edge applications.

Key Types of Adhesives and Their Uses

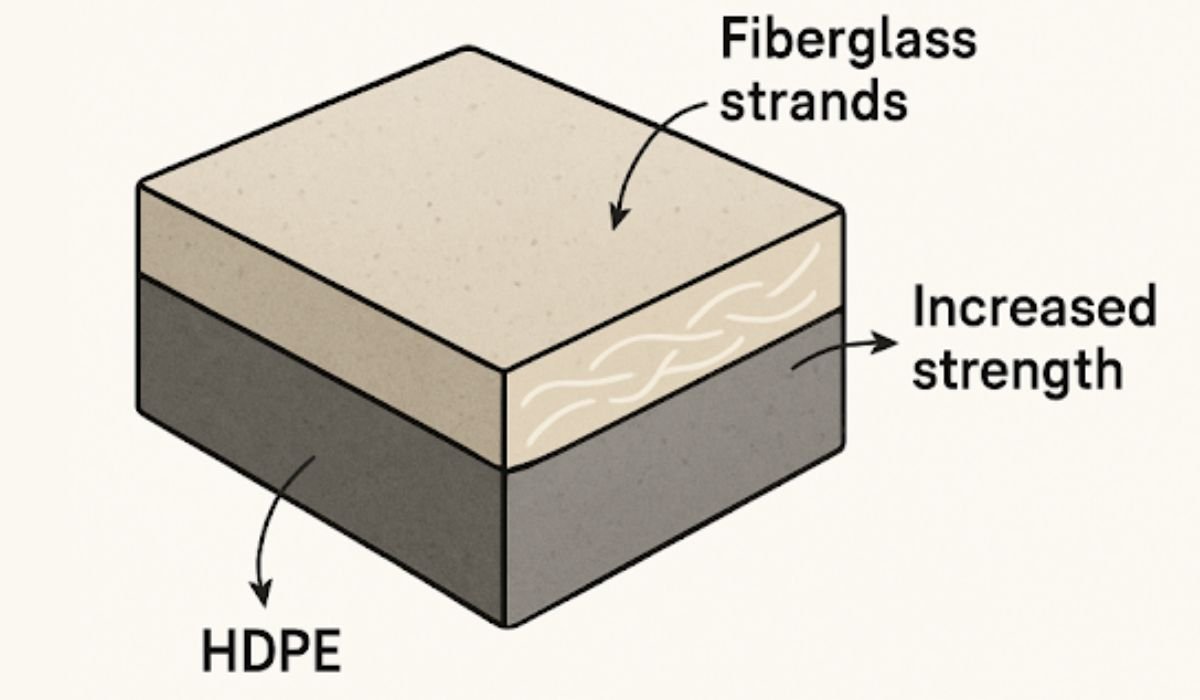

The world of adhesives is diverse, accommodating an array of bonding needs that differ by industry and application. The primary types are acrylics, silicones, and epoxies, each with unique characteristics that cater to specific uses. Acrylic adhesives are prized for their rapid bonding capabilities and consistently high strength, making them ideal for rapid assembly and durable hold. Silicones bring flexibility to the table and perform under wide temperature variances, thus being a staple in the construction and electronics sectors. Epoxies excel through their robust bonding capabilities, proving versatile in industrial settings. Their formulation enables them to adhere to a vast range of surfaces with exceptional fidelity. Delving into these adhesives’ thermoplastic and thermoset properties provides a deeper understanding of how these compounds can be optimally used in composite materials, adding valuable insights into material science and engineering.

Applications Across Industries

Adhesives significantly contribute to varied industries, although their influence often goes unnoticed. In the automotive industry, adhesives are critical in reducing vehicle weight, improving fuel efficiency, and ensuring structural integrity. This reduction in weight is crucial for meeting increasingly stringent environmental standards and enhancing performance. In healthcare, innovations in medical-grade adhesives have made strides in patient care, allowing for non-invasive procedures and enhancing the reliability of medical devices and implants. Adhesives also benefit the aerospace sector, allowing for lightweight and strong materials without compromising on safety. This capability is vital for crafting aircraft’s efficient and reliable components. The extensive use of adhesives in these situations highlights their versatile role and the unseen contributions they make to industry standards and innovations globally.

Innovative and Sustainable Development

The adhesive industry is rapidly evolving towards greener alternatives in response to mounting environmental awareness. Researchers and manufacturers focus on developing eco-friendly adhesives that perform well and minimize ecological impact. Such developments include the move towards water-based adhesives, which replace traditional solvent-based variants, significantly reducing their volatile organic compound (VOC) content and associated emissions. These innovations are about minimizing environmental footprints and adopting biodegradable materials that can naturally decompose, reducing waste. The push for sustainability in adhesive technology speaks volumes about its future, with initiatives that aim to align the industry with global environmental goals. For a detailed look into these advancements, refer to the environmental advancement report, which sheds light on strategic breakthroughs and their implications for the planet’s future.

How Adhesives Shape Consumer Products

In consumer electronics, adhesives play a vital yet behind-the-scenes role in determining product functionality and design appeal. Consider smartphones, where adhesives hold together high-tech components in a slim form factor, facilitating clean design while ensuring robustness and performance. Additionally, in the realm of wearable technology, adhesives are crucial for component integration and ensuring user comfort by enabling flexible and skin-compatible design. Beyond electronics, adhesives are integral to footwear and apparel industries, where they aid in aesthetic continuity and enhance product durability. Through thoughtful application, adhesives improve user experience across these daily used products, transforming them to be more innovative, durable, and performance-oriented.

Guidelines for Choosing the Right Adhesive

Various factors influence the selection of the appropriate adhesive, including the materials being bonded and the expected environmental conditions. Material compatibility is paramount; understanding the nuances of adhesion on different substrates can drastically affect product performance and longevity. Additionally, environmental considerations—like humidity, temperature extremes, and chemical exposure—play a critical role in decision-making. Awareness of the project’s specific requirements, such as the load-bearing capacity and expected durability under stress, further guides the selection process. Aligning these factors with available adhesive options ensures optimal results, providing long-lasting and dependable performance in various applications.

The Future of Adhesive Innovations

Adhesive technology is on the cusp of significant innovations, driven by incorporating biomimicry and nanotechnology into research and development. By taking natural cues, scientists are working to create adhesives capable of emulating biological processes, resulting in products with enhanced bonding abilities and flexibility. These biologically inspired adhesives promise unparalleled adhesion properties that can revolutionize materials’ interaction.

Furthermore, advancements in nanotechnology offer precision in application and superior strength, which could redefine standards in manufacturing and material sciences. The future of adhesives is bright and promises to intersect with emerging technologies, leading to transformative breakthroughs in various scientific and industrial fields.