In today’s fast-paced construction landscape, tracking the latest fabrication trends is vital for companies looking to remain competitive and efficient. Leveraging cutting-edge tools and techniques not only streamlines project delivery but also supports environmental responsibility and greater innovation. Companies such as Elite Weld & Fab exemplify how modern advancements in fabrication empower builders to meet evolving client needs, maintain the highest quality standards, and achieve sustainable success.

Modern fabrication is characterized by significant technological evolution. Trends such as automation, robotics, and 3D printing have redefined workflows in fabrication shops and on job sites alike. These advancements are not only making projects more cost-efficient but are also driving the adoption of sustainable building materials and methods. As markets rapidly and reliably innovate in the construction delivery industry, leaders are investing in advanced building technologies and modular construction to improve agility and resource management.

Keeping up with these continuous shifts ensures contractors and fabricators can maximize productivity, control overhead, and deliver forward-thinking solutions in construction projects of every size. In many cases, embracing modern fabrication trends strengthens business resilience and leads to greater customer satisfaction. For a deeper perspective on how 3D printing and digital tools are transforming industry norms, explore this article from Forbes.

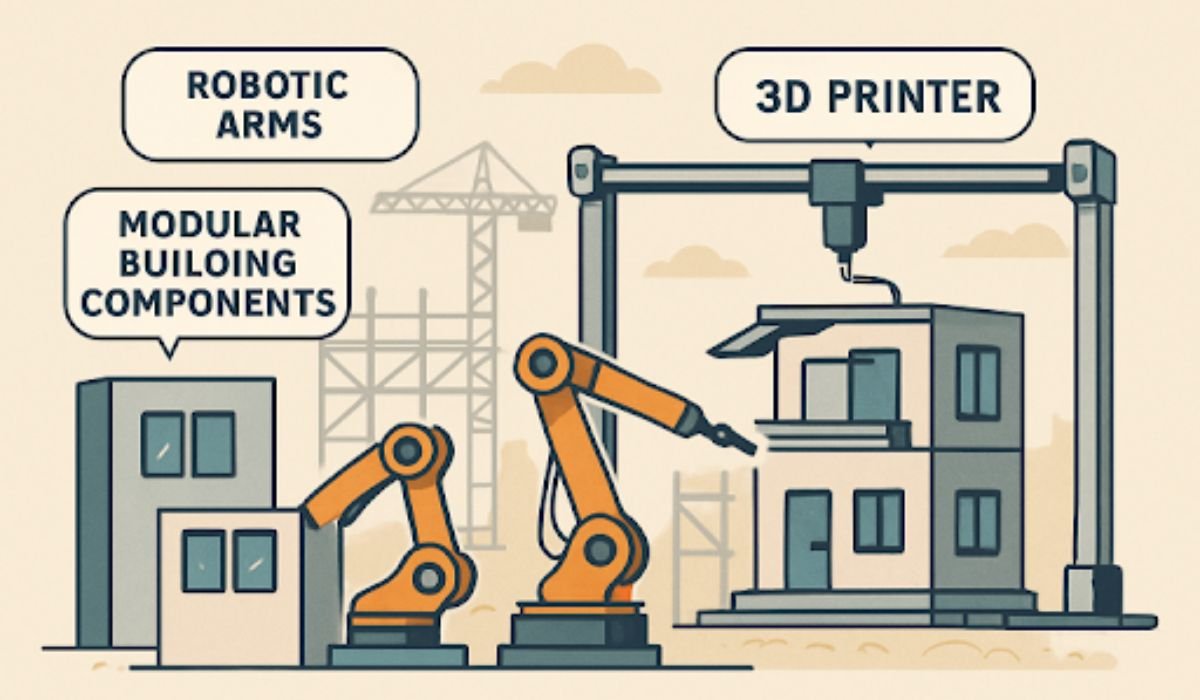

Automation and Robotics

The integration of automation and robotics in metal and construction fabrication is driving impactful improvements across the sector. Robotic welding arms and automated CNC cutting machines are now routinely deployed to handle repetitive and labor-intensive tasks. These solutions minimize human error, improve product consistency, and significantly accelerate project timelines. As of 2025, fabrication shops are increasingly investing in AI-powered inspection systems and robotic workstations. This trend is expected to continue, as demand for high-quality, large-scale construction projects rises.

The Benefits of Robotic Automation

Automated processes require less manual supervision, enabling shops to reallocate labor to more value-added activities. This not only boosts throughput but also fosters a culture of safety by reducing exposure to hazardous tasks. Additionally, improved accuracy reduces material waste and ensures a higher standard of craftsmanship for each assembly.

3D Printing in Construction

3D printing has moved far beyond a novelty and is quickly becoming a cornerstone of advanced construction techniques. New-generation printers use a variety of materials, ranging from concrete and recycled plastics to novel composites, to create intricate building components directly onsite or in nearby fabrication facilities. This manufacturing process affords unmatched precision and design flexibility, which helps architects and engineers realize even the most complex project visions.

The efficiency inherent in 3D construction printing drastically reduces both material costs and production time. Large 3D printers can fabricate walls and other structural elements in just hours or days, rather than the weeks required by conventional methods. Moreover, the layering process allows for highly customized elements that maximize strength while minimizing waste. According to Architectural Digest, 3D-printed homes and offices are already showing promise as sustainable, affordable building alternatives worldwide.

Smart Building Technology

Intelligent building systems are reshaping how prefab structures operate and interact with users. The latest prefab steel buildings come equipped with advanced sensors and integrated automation controls that enable dynamic adjustments to lighting, temperature, and security settings. For instance, a facility might automatically dim its lights during midday when abundant sunlight is available, or fine-tune its HVAC systems based on occupancy and outside weather conditions.

These technological upgrades go far beyond convenience. Innovative building technology provides significant reductions in utility bills, improves occupant comfort, and enables predictive maintenance. Building owners can access real-time data and analytics, making it easier to manage sites and ensure optimal conditions year-round. The trend toward more innovative, more connected structures is only expected to accelerate as IoT hardware and software become more affordable and powerful.

READ ALSO: Key Questions to Consider Before Renovating Your Home

Sustainable Practices

The construction sector is also moving decisively toward sustainability. Firms now emphasize green fabrication methods, ranging from recycling and reusing metallic scraps to selecting high-performance, energy-efficient machinery. Complying with ever-tightening government regulations and rising public awareness, manufacturers focus on minimizing waste output, reducing energy consumption, and using materials that promote a healthier environment.

For example, recycled steel and reclaimed aluminum not only lower the environmental impact of new construction but also provide ample strength and versatility for complex designs. Eco-friendly manufacturing advances, like closed-loop water treatment systems, reduce pollution and operational risk for fabrication shops around the world.

Modular Construction

Modular construction streamlines how buildings are created by shifting major assemblies off-site. Entire building sections or modules are fabricated and completed in controlled factory environments, then transported and assembled swiftly on-site. This process greatly enhances project speed and cost-effectiveness.

Metal fabrication is essential in producing precision-made frameworks, fasteners, and panels for modular units. Controlled conditions help ensure quality and consistency while slashing common construction delays due to weather or labor shortages. As modular construction adoption grows, it enables greater scale, customization, and sustainability in residential and commercial projects.

Advanced Materials

The introduction of next-generation materials is further revolutionizing modern fabrication. Lightweight aluminum alloys enable faster, safer handling without sacrificing strength, while advanced carbon composites are being adopted for applications that demand high durability with minimal material use. Many of these materials are engineered for longevity, recycled content, and performance under extreme conditions.

New material innovations also facilitate more energy-efficient, environmentally responsible construction outcomes. Their adaptability is helping architects and engineers push the boundaries of design, opening new possibilities for the built environment. Globally, the focus on advanced materials is likely to expand as the construction sector seeks a balance between performance, cost, and environmental stewardship.

Conclusion

The momentum behind modern fabrication trends is reshaping the construction industry’s future. Adopting technology-led processes such as automation, 3D printing, and intelligent systems increases efficiency, enhances sustainability, and enables the delivery of cutting-edge projects. Remaining agile and well-informed about these trends is the key to ongoing success and growth for builders and fabricators across the industry.

YOU MAY ALSO LIKE: Innovative Building Methods for Modern Homes